Jobs

Ready to Work: How Arizona is preparing for the semiconductor job rush – Phoenix Business Journal

As a security guard at Taiwan Semiconductor Manufacturing Co.’s factory site in north Phoenix, Meareg Mamo has a front row seat for the growth of the Valley’s semiconductor industry.

It’s also sparked Mamo’s interest in changing careers with the goal of someday working alongside other TSMC microchip technicians. Mamo, who has IT experience, sees an opportunity to build a long-term career in the chip industry.

“Chip factories are growing fast, big companies are coming to Arizona and need a lot of workers,” he said.

In April, Mamo was accepted into Quick Start, a 10-day semiconductor technician training program created by Maricopa Community Colleges and industry partners.

“I like the class setup and modules. It’s easy to understand,” he said. “It’s good for people who want to progress in the future.”

By the end of the decade, the U.S. semiconductor industry is projected to face a shortage of 70,000 workers needed to run fabs and make chips used in computers, smartphones, appliances and vehicles, according to the Semiconductor Industry Association.

In Arizona, TSMC and Intel are set to receive billions of dollars in federal CHIPS Act funding to build out their fabs. The two companies expect to create a combined total of more than 9,000 manufacturing jobs.

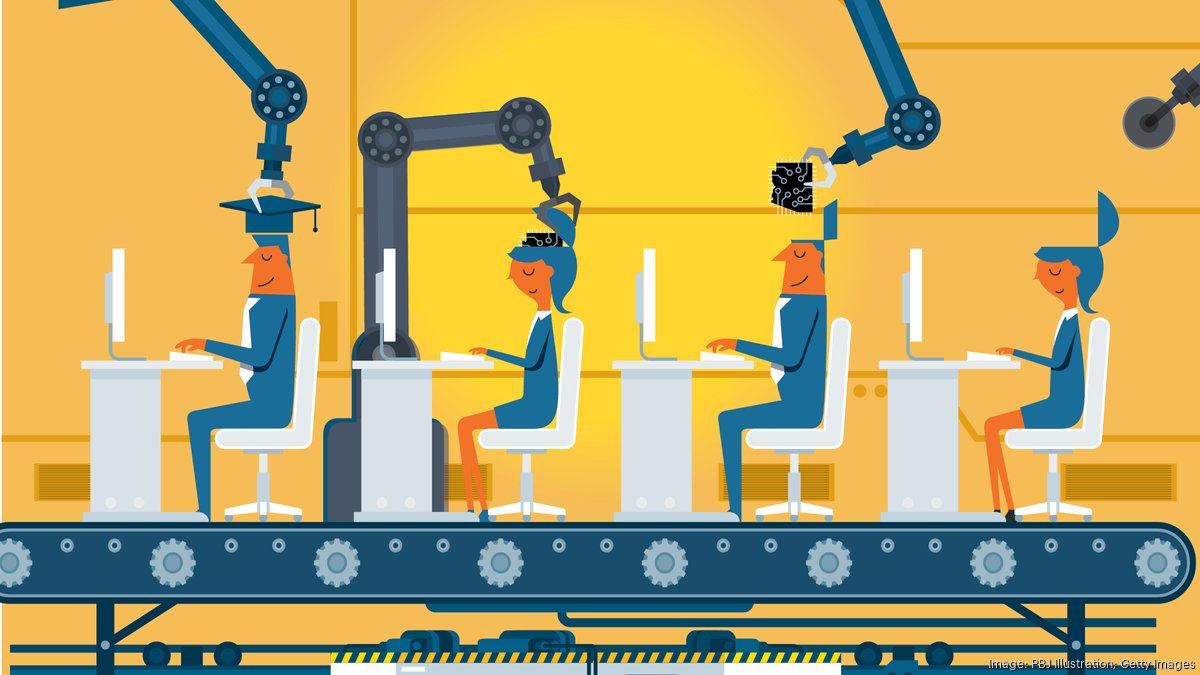

To answer the call for skilled workers, companies, academia and state officials are championing a handful of apprenticeship programs — including the Quick Start program — to prepare students for semiconductor jobs in what’s projected to be a booming industry.

But there’s a challenge: semiconductor companies have reduced hiring in the near-term amid economic uncertainty and slowing demand, leaving students in apprenticeship programs to wonder when jobs will be available.

The Quick Start program has held 83 classes since its inception in 2022. More than 900 students have participated in the program and 864 obtained semiconductor technician certifications, said Leah Palmer, executive director of AzAMI Workforce/Manufacturing Technologies at Maricopa County Community Colleges.

Despite the program’s initial success, it had to temporarily reduce the number of classes it offered in response to a decline in job openings, Palmer said.

Students learn skills to become semiconductor technicians in the Maricopa Community College Quick Start program.

“We did not want to put people out there that were not going to get employed,” Palmer said. “That would not be fair to them. We ramped down now and it’s going to pick up probably by the fall, which is what we’re being told. Then, we’ll start ramping back up the number of courses that we have. It’s trying to keep pace with industry.”

For its part, a TSMC spokesperson told the Business Journal that “hiring at TSMC Arizona is active and ongoing for technician, engineering and business support positions.”

Interest in the QuickStart program remains high. It has a waitlist of hundreds of students with the next round of classes slated to begin in August, according to the Maricopa Community Colleges website.

While the Quick Start program is hosting a job fair in May, companies are mostly looking to backfill for attrition as they have experienced a demand slowdown that started in September 2023, Palmer said.

“And the data supports that, so it’s not like they just don’t want to hire. It’s actually part of the ecosystem,” Palmer said. “But what’s difficult is that some of these students had waited a year to get in from the very beginning. And now they’re getting their skills ramped up and they’re ready to go.”

Partnerships key for skilled workforce

In 2022, the state of Arizona allocated $100 million to enhance semiconductor infrastructure, workforce and research while spurring private sector investment.

Applied Materials and Arizona State University received $47.5 million to establish the first of its kind materials-to-fab laboratory at the university’s MacroTechnology Works facility to support advanced packaging and GaN capabilities. In addition, the state established its first registered apprenticeship program with NXP Semiconductors to support the semiconductor industry.

In January, TSMC invested $5 million to establish a new semiconductor technician registered apprenticeship program. The program kicked off in April with its first cohort of eight apprentices. The program, which is expected to run 18 to 24 months, will scale over five years with an initial goal of training 80 local facility technician apprentices, a TSMC spokesperson told the Business Journal.

• Fast fact: Over the past five years (March 2019 to March 2024), the Arizona labor force increased by 9.7%, or 331,188 workers. During this same period, unemployment declined by 14.2%, or 23,669 people. (Source: US Bureau of Labor Statistics)

Other apprenticeship programs for skilled trades include the Future48 Workforce Accelerator and the BuilditAZ Apprenticeship Initiative.

Palmer said partnerships between the state, academia and industry are “absolutely necessary” to ensure a skilled workforce.

“Industry is crying for talent. But we have to find mechanisms to bridge between not having an opportunity and growing them internally,” she said. “And that’s what really is my next big push.”

The next step needed is to implement a “train the trainer” process in which industry experts teach semiconductor industry skills to instructors to help gain a deeper level of understanding in high schools, she said.

“I feel like we need to drill down Quick Start into some high school opportunities and bootcamp opportunities for summer camps,” she said.

West-MEC creating workforce pipeline

Western Maricopa Education Center, a public high school career and technical education center that serves more than 40,000 students in Maricopa County, has already been engaging with TSMC to develop curriculum.

In late 2022, West-MEC Superintendent Scott Spurgeon met with TSMC’s former chief human resource officer, Scott Holman, to discuss the school’s potential for providing career education, training and credentials specifically for the semiconductor industry.

With the help of TSMC’s technicians, West-MEC is designing a semiconductor training program for students.

In addition, Spurgeon spearheaded efforts to expand West-MEC’s northeast campus to house an advanced manufacturing facility that includes semiconductor technician training.

“Later this fall, we’ll be breaking ground on phase one of that process,” Spurgeon said. “So we’re not just talking about it, we’re putting our money where our mouth is because that partnership with TSMC for West-MEC is as tight as it gets.”

Scott Spurgeon, superintendent, West-MEC

For academia to properly prepare a pipeline of skilled workers, schools need to know the type of skill sets required by companies, programs that align with their needs and how many people they expect to hire. Oftentimes, companies will engage with academia after their fabs are built and that’s too late, he said.

“Then, we’re probably 12 to 18 months out to being able to provide some sort of workforce development pipeline in those areas,” Spurgeon said. “If we had known that 14-16 months earlier, we could have been developing that all along and by the time that facility is done, we’ve got kids coming out of those programs that might have interest in moving into that organization.”

• Fast fact: Arizona Computer and electronic parts manufacturing, which includes semiconductor manufacturing, is projected to grow by 13% and add 4,470 jobs through 2032. Over 95% of the growth within this industry is projected to occur within Maricopa County. Source: U.S. Bureau of Labor Statistics.

In February, Holman, the former TSMC executive, was named CEO of the Arizona Education Economic Commission Foundation. The commission is a public-private collaboration that includes more than a dozen companies in manufacturing, health care, technology and defense.

Holman said his goal is to ensure alignment between educational institutions and industry executives to spur workforce development initiatives, in addition to fundraising to support the commission’s goals. The commission has launched seven industry workgroups, including semiconductors, to discuss workforce development and identify academic programs that meet skillsets of the most in-demand jobs, he said.

A big push for the commission is encouraging industry to engage with the more than 550,000 middle and high school students in the state to share information about potential jobs in advanced manufacturing, Holman said.

Scott Holman, CEO of the Arizona Education Economic Commission.

While the commission isn’t expecting companies to share an exact number of workers it expects to hire, it’s requesting a ballpark figure for what they need over the next three years to help CTE programs create certificate programs, Holman said.

Carlos Contreras, director of the Arizona Office of Economic Opportunity, echoed that industry needs to be involved in efforts to meet future workforce demand.

The state is leading a marketing campaign with the trades and the semiconductor industry to reach more women and underrepresented groups, he added.

What’s more, the Arizona Pipe Trades is expanding its Joint Apprenticeship Training Center with a $15 million investment from TSMC. The center is intended to train the workforce needed to build semiconductor fabs in the Valley.

The state applied for a U.S. Department of Labor grant to establish a potential apprenticeship “hub” for several industries. It expects to hear back about the grant by July.

“There’s a lot of interest in not only semiconductors, but in health care, early childhood, and construction, of course,” Contreras said. “We have a lot of industries that are saying, ‘Yeah, I’m interested,’ and so knock on wood that we get the grant. But even if we don’t get the grant, we’re going to build initiatives (for) these other industries.”

Arizona community colleges have played a key role in designing curriculum to meet workforce demand. It’s imperative, he said, that the state, academia and industry leaders are diligent about building an apprenticeship model with shared responsibility and instruction.

“I think there’s a lot of people that want to do a lot of good in this space. But I think at the end of the day, employers have to tell us what they want and that’s the key,” Contreras said. “If we listen to the employers, we can bring the training providers, community colleges, and trades to the table, then we can move these things forward.”

‘Promoting value propositions’

In the Quick Start program, students receive a mix of lectures and hands-on labs. They also practice with troubleshooting equipment and tools used in a chip factory. Throughout the 10-day program, students learn about circuits, schematics, safety hand tools, clean room protocols, lean manufacturing and model-based problem solving.

Students in “bunny suits” learning skills to become semiconductor technicians in the Maricopa Community College Quick Start program.

According to an employment outcome survey, 33% of students indicated they obtained employment in the semiconductor industry after completing the Quick Start program. It’s challenging, however, to measure an exact number of students with technician credentials who are working in the semiconductor industry as they have to self-report their status and not all of them do, Palmer said.

A bright spot for the program, Palmer said, is that even though it was designed specifically for the semiconductor industry, model-based problem solving and lean manufacturing skills often translate to other industries.

In addition, the Quick Start program credits are stackable with other electrical or safety training courses, potentially allowing students a pathway to a higher-level position within a company.

“All of these pieces of the curriculum are intentional. What we didn’t know when we did it was that there are other organizations out there that need the very same skills,” Palmer said. “So part of what we’re doing now during this downtime, is we’re actually promoting Quick Start’s value propositions to these other companies.”

Michael Charap was driving for Uber when a passenger told him about the Quick Start program, which he applied for in March and was accepted into the April class at Mesa Community College.

Charap, who has experience in business, cloud computing and is fluent in Spanish and Japanese, wanted to get his foot in the door in the semiconductor industry.

Prior to the Quick Start program, he applied for jobs at TSMC, but didn’t receive a response from the company.

“I decided to change my approach and come in at whatever level I could,” he said.

Charap said he heard about the hiring lag in the semiconductor industry and plans to build upon his skills while waiting for activity to ramp back up. He’s updating his resume, brushing up on foreign language skills and learning everything he can about the schematics for the machines used in fabs.

The Quick Start program has been valuable in furthering semiconductor industry knowledge, Charap said.

“It gives us a basis for a lot of things – schematics, electrical and we can expand on that knowledge,” he said.

:max_bytes(150000):strip_icc()/roundup-writereditor-loved-deals-tout-f5de51f85de145b2b1eb99cdb7b6cb84.jpg)