BINGHAM — Charlie Martin describes what he has been working on in Bingham for the last few years as akin to the TV show “This Old House.”

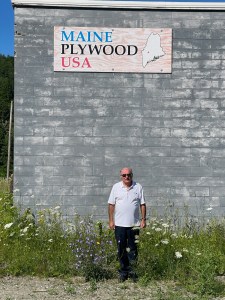

Charlie Martin, owner of Maine Plywood USA, is shown outside the Bingham mill where he is trying to open a plywood factory in this undated photo. Photo courtesy of Charlie Martin

But instead of fixing up an old home, Martin is trying to resurrect an old mill that’s been vacant for more than a decade and turn it into a plywood factory.

When it opens, Maine Plywood USA is expected to employ about 110 people. It would be the only plywood manufacturer in New England, and the only one in North America making its specific product. And it could expand domestic manufacturing of a product that today is largely imported from Asia.

“We’re taking this old, old building that sat dormant there for 14 years,” Martin said, “and bringing it back to life.”

Through millions of dollars in investments — a combination of his own savings and support from several state and regional public-private partnerships — Martin has pieced together most of the equipment he needs to open the plant. Finding private equity investors, though, has been challenging, but funding needed to open the mill could be finalized soon, Martin said.

“Getting the loan is the challenge because we’re a new startup,” Martin said.

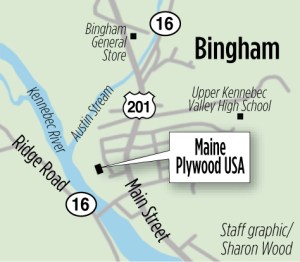

For a town of less than 1,000 people in one of Maine’s most economically challenged counties, the project is expected to have a major impact. The mill, which has housed various companies since it was constructed about a century ago, including the Quimby veneer mill, once employed about 300 people.

“We feel it will really be a catalyst for the entire area,” said Christian Savage, executive director of the Somerset Economic Development Corp., the county’s economic development agency.

A YEARSLONG QUEST

Martin, who is based in Chicago, has been in the plywood business for more than 30 years. He worked for MacMillan Bloedel, which was a major company in the forest products industry before it was bought by another industry giant, Weyerhaeuser.

Martin was put in charge of a plywood mill in Nipigon, Ontario, which eventually was purchased by a local group of investors, he said. There, the company made a specialty product called multi-ply plywood underlayment. Martin grew its distribution from coast-to-coast across North America.

“We became the No. 1 brand in the industry for like 10 years,” Martin said. “And we had a good thing going for a long time.”

Then, in 2007, the mill burned down.

To satisfy his customers’ demand, Martin began importing plywood through his own company, Ontario Plywood. His competitors were doing the same, he said.

Martin’s goal then became to open his own plywood production facility in North America.

“I’ve been in the quest of building a plywood mill for years,” Martin said.

Mark McCollor walks through the building Tuesday that will be used in the initial phases of the plywood-making process at Maine Plywood USA in Bingham. Rich Abrahamson/Morning Sentinel

In recent decades, most plywood used in the U.S. has been manufactured overseas, according to Martin and Savage. Domestic plywood is largely produced in the Pacific Northwest. Similar products, like oriented strand board, are made in New England, including a planned factory at the former Androscoggin Mill in Jay.

First, Martin was importing from China. At one point, the U.S. put a large duty on Chinese plywood, and Chinese companies shifted production to other Asian countries, like Indonesia. But the quality of that product was subpar, and Martin said he began importing from Russia. When the conflict between Ukraine and Russia broke out, Russian plywood also became expensive, according to Martin.

“If someone had told me like 10 years ago, ‘Charlie, you’re going to be buying plywood from China and Russia,’ I would’ve said you are totally crazy, you’re nuts,” Martin said.

PIECING IT TOGETHER

Martin said he found out about a former plywood mill for sale in northern Quebec. He explored reopening it himself, even getting a wood allocation from the government. For various reasons, the project did not work out.

But the owner of the mill offered to sell the equipment and machinery, and Martin took the deal in 2021.

“It was such a good deal — I bought it,” Martin said. “It was sort of like the idea of the ‘field of dreams.’ I’ll build this plant, I think people will come. That’s how naïve I am.”

A group of buildings shown Tuesday comprise Maine Plywood USA’s property in Bingham. Rich Abrahamson/Morning Sentinel

The next challenge was finding a place to put it, he said. Martin looked to Maine, where there is a large supply of poplar, a type of wood generally underutilized but ideal for his product, he said.

Martin said he called around the state to various agencies, but nothing worked out — until he contacted Savage, the head of SEDC, the county economic development agency.

“The reason this plywood mill is being built in Somerset County is because of Christian Savage,” Martin said of the Somerset Economic Development Corp. executive director.

Local, county and state officials had been looking to revitalize the former Quimby mill in Bingham, Savage said. After doing some research on the possibility of plywood manufacturing in Maine, the conversations with Martin grew more serious.

“That was definitely on our radar to try to repurpose that, and so when Charlie had interest, we were pretty excited,” Savage said.

Martin bought the mill site later in 2021. After sitting vacant for more than a decade, the facility was in rough shape: It took $30,000 worth of dumpsters to clear it out, Martin said. Parts of it still need major work, like an area where the roof collapsed from the weight of snow.

Mark McCollor looks at equipment Tuesday that will be used in the beginning phases of the plywood-making process at Maine Plywood USA in Bingham. Rich Abrahamson/Morning Sentinel

The 25 truckloads of machinery from Quebec were moved in, and Martin has cobbled together other equipment. He bought a 110-foot-long dryer — used to dry the veneer before gluing the plies together — from a sawmill in Kentucky for a fraction of its normal cost. That took 16 truckloads to move, Martin said. He bought a biomass system to power the facility. That took another 14 truckloads.

Martin also salvaged two large boilers from the former B&M Baked Beans plant in Portland, he said. He had been looking for boilers that put out enough pressure, 300 pounds per square inch, for two years.

On a recent tour of the facility, Mark McCollor, who is Martin’s right-hand man on the ground in Bingham, said work is slowly beginning to bring all of the components together.

“We’ve got almost all of what we need,” he said.

Though much of the space is still empty, McCollor pointed out the whole process, from where logs enter the facility to where veneer is produced to where the layers of wood are glued and pressed together. The equipment can produce different sizes and kinds of plywood products, McCollor said, but the main product will be Martin’s multi-ply underlayment.

Mark McCollar crouches near the opening of a 4-foot-diameter pipe on Tuesday while discussing how the pipe will carry fuel to a boiler, which is part of the plywood-making process at Maine Plywood USA in Bingham. Rich Abrahamson/Morning Sentinel

Initial plans for production facilities will take up about 60,000 square feet, according to McCollor. The mill is made up of several, separate buildings on a roughly 2-acre property, much of which will not be used at the beginning, he said.

‘READY TO GO’

McCollor, 62, and now retired, has lived in Bingham for most of his life. He remembers visiting the mill when his father worked there as a production manager. McCollor also worked at the mill for more than 20 years as a maintenance supervisor.

Maine Plywood USA will bring manufacturing jobs back to Bingham, which the town had for decades, McCollor said.

Locally, the development of the mill will increase tax revenue, Savage said, and the creation of more than 100 jobs will also benefit the greater region.

The wide-ranging impacts of opening the mill are what has drawn the attention of various agencies across the state, Savage said. SEDC, in partnership with Somerset County, provided a $250,000 loan to Maine Plywood USA, similar to what it did for Madison-based manufacturer TimberHP. The agency also helped obtain a federal grant for Martin to purchase the veneer dryer.

In February, Maine Plywood USA was awarded nearly $1 million from the state for its biomass-fueled power system. Other partners, offering financial and other kinds of assistance, include the Finance Authority of Maine, the Maine Rural Development Authority, and the state Department of Economic and Community Development, according to Savage.

Once he gets the needed funding to complete construction of the production facility, Martin has his eyes on expanding. And that expansion is less about making more money, and more about creating more jobs, Martin said.

“It’s a gem, we believe,” said McCollor of the building. “And we’re ready to go.”

Related Stories

:max_bytes(150000):strip_icc()/roundup-writereditor-loved-deals-tout-f5de51f85de145b2b1eb99cdb7b6cb84.jpg)